D11 D13 D16 engines This is a comprehensive engine workshop service manual for D11 D13 D16 engines. This manual has been written in a format that is designed to meet the needs of Volvo technicians worldwide. Related products. Volvo Penta 5.0/5.7 GXi Workshop Service Repair Manual $ 15.99 Add to cart Volvo L90f Wheel Loader Service Repair Manual $ 29.99 Add to cart Volvo dumper A25D A30D Service Repair Manual Pdf.

- VOLVO D13 ENGINE provide input to the EMS:. Ambient Air Temperature Sensor 1.1 SYSTEM OVERVIEW. Ambient Pressure sensor NOTE. Boost Air Pressure (BAP) Sensor The “Premium Tech Tool” (PTT) is the. Camshaft Position (Engine.

- VOLVO D13 USER MANUAL Pdf Download. Exploded views / schematics and spare parts for Volvo. Volvo Trucks - Cooling System Volvo D13 Engine Cooling Diagram INSTALLATION PROCEDURE FOR VOLVO D-SERIES HEAVY DUTY ENGINES Volvo Trucks. Driving Progress VOLVO D13 Engine family 2015 Volvo D13 Coolant Filter Shut Off Genuine Volvo Truck Parts - Buy.

Volvo Genuine Overhaul is available to provide Volvo Genuine Parts, expert service and great value. If your engine is showing any of the following signs: decreased fuel economy, poor responsiveness, hard start, excessive oil consumption, or excessive exhaust smoke, an overhaul could be the solution.

Description

VOLVO Truck D11 D13 D16 Engine Service Repair Manual Download

Covers: VOLVO Truck D11 D13 D16

Format: PDF

Size:300Mb

Language: English

Requirements: Adobe PDF Reader & WinZip

Compatibility: All Versions of Windows & Mac/IPAD

This is a comprehensive engine workshop service manual for D11 D13 D16 engines . This manual has been written in a format that is designed to meet the needs of Volvo technicians worldwide. You will never be dissapointed with the content of this workshop manual (not a scanned version)

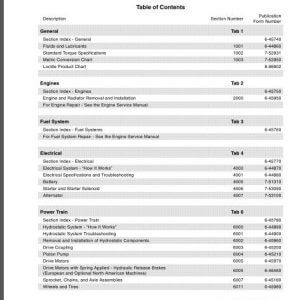

CONTENTS AS FOLLOWS:

Lubrication and Oil System Design and Function.pdf

Main Bearings Replace.pdf

Nox Sensor and Control Module Replacement Compact.pdf

Nox Sensor and Control Module Replacement Vertical.pdf

Oil Cooler Replacement.pdf

Oil Pump Replacement.pdf

Overflow Valve Replacement.pdf

Particulate Filter Insert Replacement Compact.pdf

Particulate Filter Insert Replacement Vertical.pdf

Piston Cooling Nozzle Replacement.pdf

Pistons and Liners Replace.pdf

Rocker Arm Checking.pdf

Safety Valve Oil Pressure Replacement.pdf

Sealant Timing Gear Plate Replacement.pdf

Solenoid Valve VCB Replacement.pdf

Thermostat Replacement.pdf

Thermostat Valveor Oil Pressure Valve Oil Cooler Replacement.pdf

Threads in the Engine Block Cleaning.pdf

Timing Gear Cover Replacement.pdf

Turbocharger Replacement.pdf

Unit Injector Clean.pdf

Valve Guide Wear Check.pdf

Valve Seat Replacement One.pdf

Valves and Unit Injectors Adjustment.pdf

Valves Remove and Install.pdf

Viscous Fan Checking.pdf

Actuator Variable Geometry Turbocharger Replacement.pdf

Aftermarket Injector Replacement.pdf

Aftertreatment Injector Clean.pdf

Aftertreatment Shutoff Valve Replacement.pdf

Air Intake Pipe Turbocharger Replacement.pdf

Camshaft Bearing Brackets Replacement.pdf

Camshaft Replacement.pdf

Camshaft Wear checking.pdf

Connecting Rod Bearing Replace.pdf

Coolant Replacement.pdf

Cooling System Clean.pdf

Cooling System Troubleshooting.pdf

Crankcase Ventilation Separator Replacement.pdf

Crankshaft Seal Replacement Front.pdf

Crankshaft Seal Replacement Rear.pdf

Cylinder Head Pressure Test.pdf

Cylinder Linerand Piston Wear Check.pdf

EGR Cooler Pressure Test.pdf

EGR Pipe Replacement.pdf

EGR System Design and Function.pdf

EGR Venturi Tube Replacement.pdf

Emission Label Clean Idle.pdf

Engine Brake Design and Function.pdf

Engine Control Unit Replacement.pdf

Exhaust After Treatment System Design and Function.pdf

Exhaust Aftertreatment System Fault Tracing.pdf

Fan Literature.pdf

Filter Water Separator Replacement.pdf

Flywheel Bearing Replacement.pdf

Flywheel Ring Gear Replacement.pdf

Flywheel Sensor Depth Check.pdf

Flywheel Sensor Distance Check.pdf

Fuel Overflow Valve Replacement.pdf

Fuel System Design and Function.pdf

Fuel System Specifications.pdf

Fuel System Troubleshooting.pdf

Hose Clamps Charge Air Cooler Replacement.pdf

Injector Aftertreatment Clean.pdf

Intake and Exhaust System Design and Function.pdf

Intake Manifold Gasket Replacement.pdf

Transmission

D13 Engine Review

- Integrated Communications Benefits: The DT12® transmission links engine to axles, and communicates with the DD13® and DD15® on an integrated electronics network to share damage-reducing information such as clutch overloading and driveline protection.

- Super-Finished Gears: Tightly-spaced 12-speed gearing, now with 'super-finished' gears in the new DT12® available for the new Cascadia and Western Star 5700XE, improves low-speed maneuverability, making the Detroit® Powertrain not only strong and efficient, but also smooth and safe to operate as well.

- Intelligent Powertrain Management (IPM): The DT12® uses information from a topographical map to manipulate both engine and transmission functions, taking advantage of the truck's surroundings. IPM4 refines the parameters of this technology, making the truck even more capable of utilizing its surroundings efficiently.

- Transmission Benefits: The DT12's direct drive and over drive gearing, along with eCoast, are integrated with the downsped engine — which now idles at a lower 500RPM when off-throttle — for optimized fuel economy.